|

3D Print Radio Parts (N4HCI) |

3D Printing

The "Maker' hobby has been growing in popularity for years. The

term "Maker' does not describe any one thing, but is a collective term

for people making their own proejcts. It easily includes sewing,

hand crafts, wood work, metal work, foundry work, making things with

Arduino computers, etc.

3D printing is part of the maker hobby and one that I have only

recently joined. 3D printers suitable for home use come in many

sizes, different eases of use, and prices. I selected a very

inexpensive Chinese product with a large build volume (ANET E12) which I

bought in early February 2017. [CAUTION. This is a rather

high maintenance 3D printer. A number of the more expensive units

are much easier to use and lower maintenance but it seems that part of

the 3D printer 'Maker" hobby is to improve the printer itself and make

it better - but that is a story for a different time.]

For Hams, the 3D printer provides a means to manufacture parts for your

radio, the shack, and your antenna. I have seen projects where people make

knobs, buttons, labels, CW keys, microphones,

coil winding spools, kit enclosures, portable satellite tracking

antennae, radio cases, microphone holders, chassis feet, stands for

positioning a raised radio front edge, Call Sign displays, antenna

insulators, etc.. Inspired by these efforts, I decided to

use my new 3D printer and see what I could do.

After a couple of months I have manufactured

- a microphone body and assembled it into a working microphone, and

- an adapter sleeve to allow use of available radio knobs on undersized

shafts

And following these modest starts, I am now working on the printing of

a home designed uBITX radio enclosure.

3D Printing Workflow

3D printing is a multi-step process. The first step is to either

acquire from someone who made it, or make a model yourself, of the

product to me printed. In my case, I use Adobe's Autodesk Fusion

360, a very capable design development platform. Other design

software, easier to

use but somewhat more limited in their abilities, exist, such as

TinkerCAD. The purpose of the modeling phase is to develop the

look and feel for the object, to include all dimensions of all

internal and external features necessary to the purpose of the object

being designed. At the end of the modeling phase, all of the

models parts must fit together just as they will when they exists a

physical objects. The end result of the design will be a file

saved in a format appropriate to the design software, but the design

software also needs to export the design in a format that can be read by

a 3D printer slicer program. A common file format for this purpose

is the .STL format.

The slicing program reads the STL file and presents the model on a

visualization of the 3D printer bedplate, where it can be manipulated

into the proper position for printing, and where the user specifies the

specific printing facts and instructions necessary for the printer to do

its job. These include such things as nozzle size, printing medium

(type and size of type of plastic filament being used), layer size, wall

thickness, printer head travel speeds, temperatures for the nozzle (as

appropriate to melt the plastic filament type) and bedplate (help adhere

the print to the bedplate during the printing process), and whether to

make the interior solid or filled with an Infill of less than 100%

plastic. Once these have been specified, the program slices the

object into a series of layer by layer instructions that tell the

printer how to move the print head, and bedplate, and how much plastic

to extrude so that the printer can make each layer. In my case, I

use Cura, a free slicer program from the Ultimaker 3D printer folks.

The output program from the slicer program that is used by most printers

is usually in .GCODE format.

The printer then reads the GCODE file and prints the object described by

it, layer by layer, until finished. Print layers can be 0.1 mm in

vertical thickness, taking 10 layers to make 1 mm and a large number of

layers to make an object of any size.

Printing can take a long while. Prints lasting more than a day are

fairly common and the uBITX enclosure described below will take over two

days.

Microphone

While waiting 2 months for delivery of my uBITX radio, I decided to make

its enclosure out of 2-sided PCB material (see that project

here) and to make a microphone

out of a Radio Shack push button, an electret microphone element, and a

coiled 4-wire telephone cable, all available from the junk box.

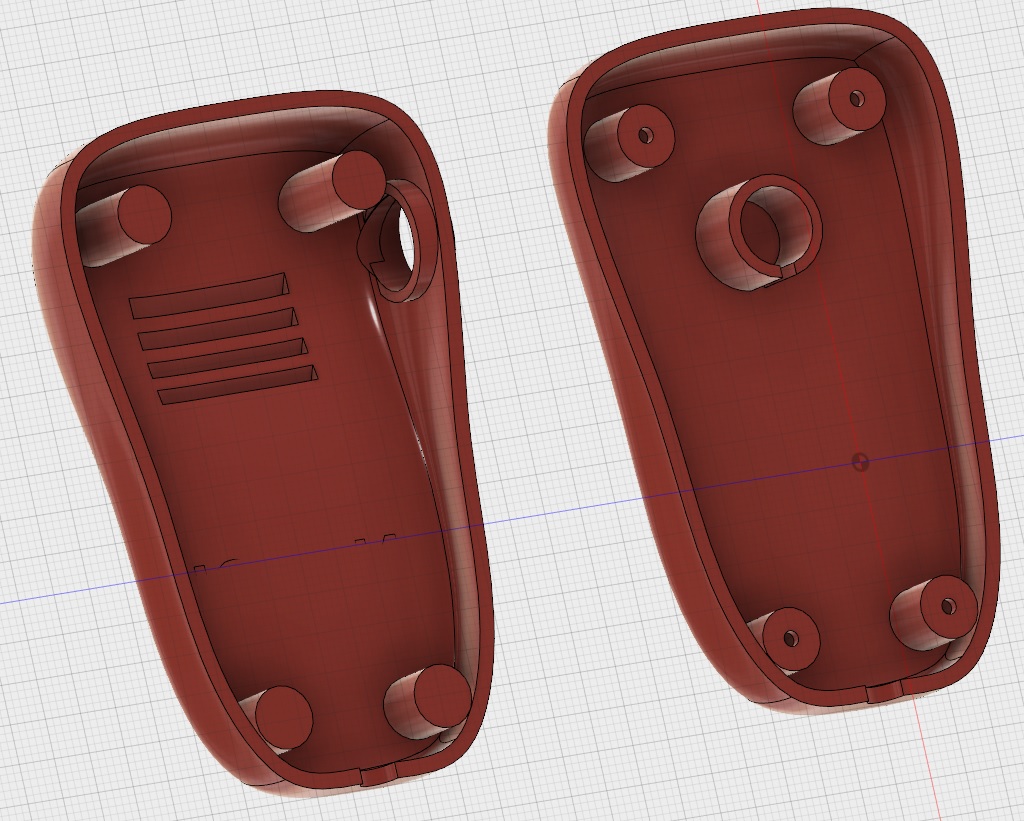

The microphone model design needed to be two parts that included a front

shell, a rear shell. The shells needed to include a hole for the

microphone cable, a hole to mount the push button, slots for my voice to

pass through to reach the electrect element, an internal bracket into

which the electret element would snuggly fit, and some posts that

would allow the shells to be screwed together. At the end of the

modeling, the microphone looked like:

A video short of the printer at about 10% of the shell back can be seen

here.

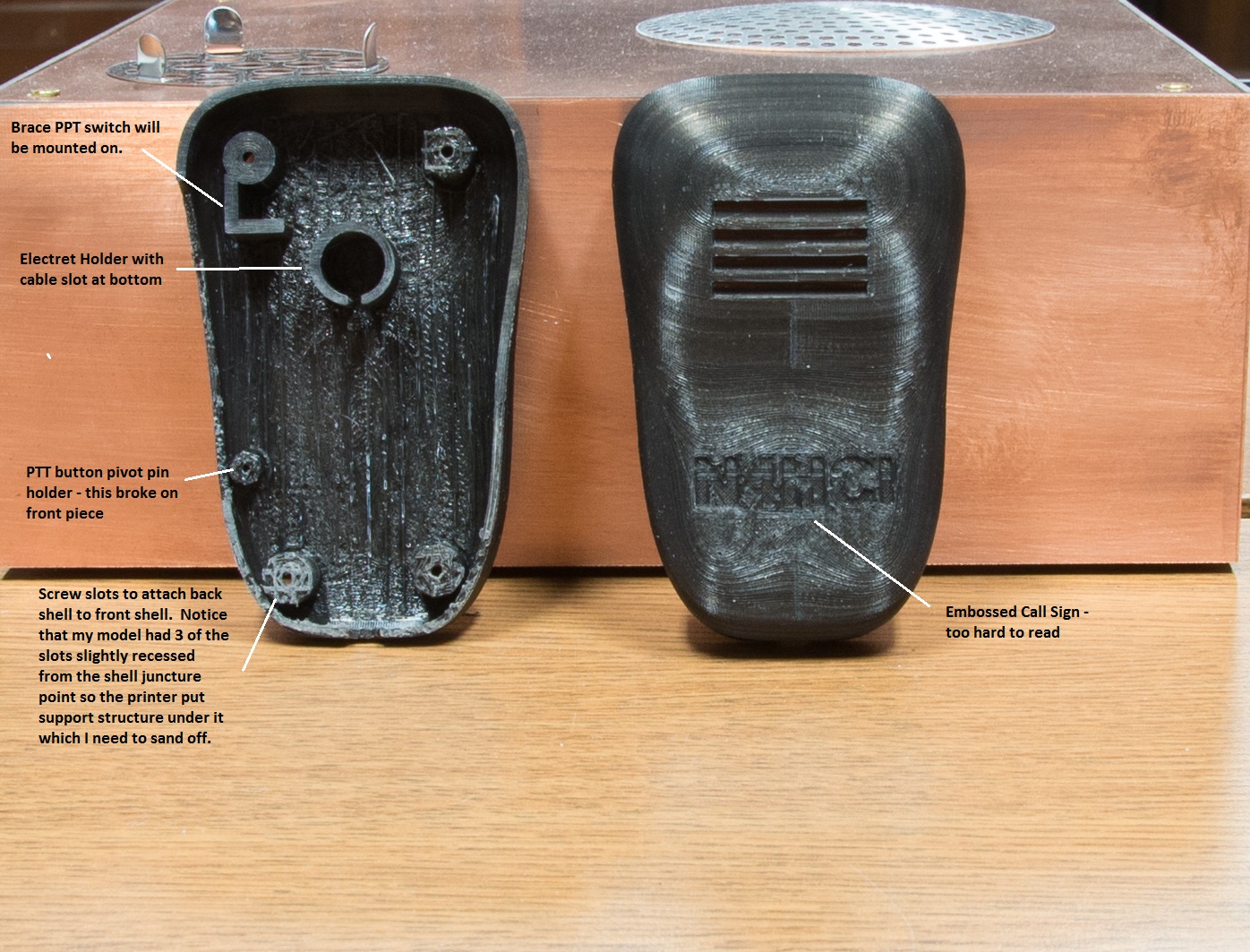

For me at least, 3D printing is an iterative process with early prints

not necessarily being the final prints. Errors discovered in the early

prints lead to design changes and a reprint. The above design was

the 2nd design after printing the initial design (see below) and deciding that it

needed to be changed. The 2nd design eliminated the original

intention to 'make' the PTT switch instead of installing it, fixed some

dimensional errors, and made the embossed call sign deeper.

The end result of the redesign was

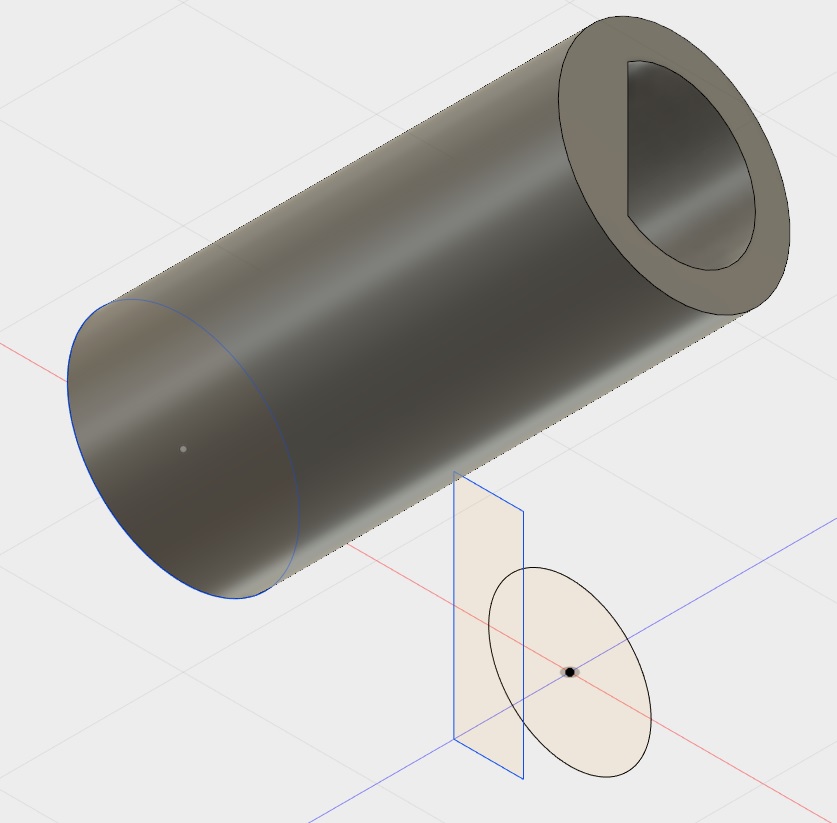

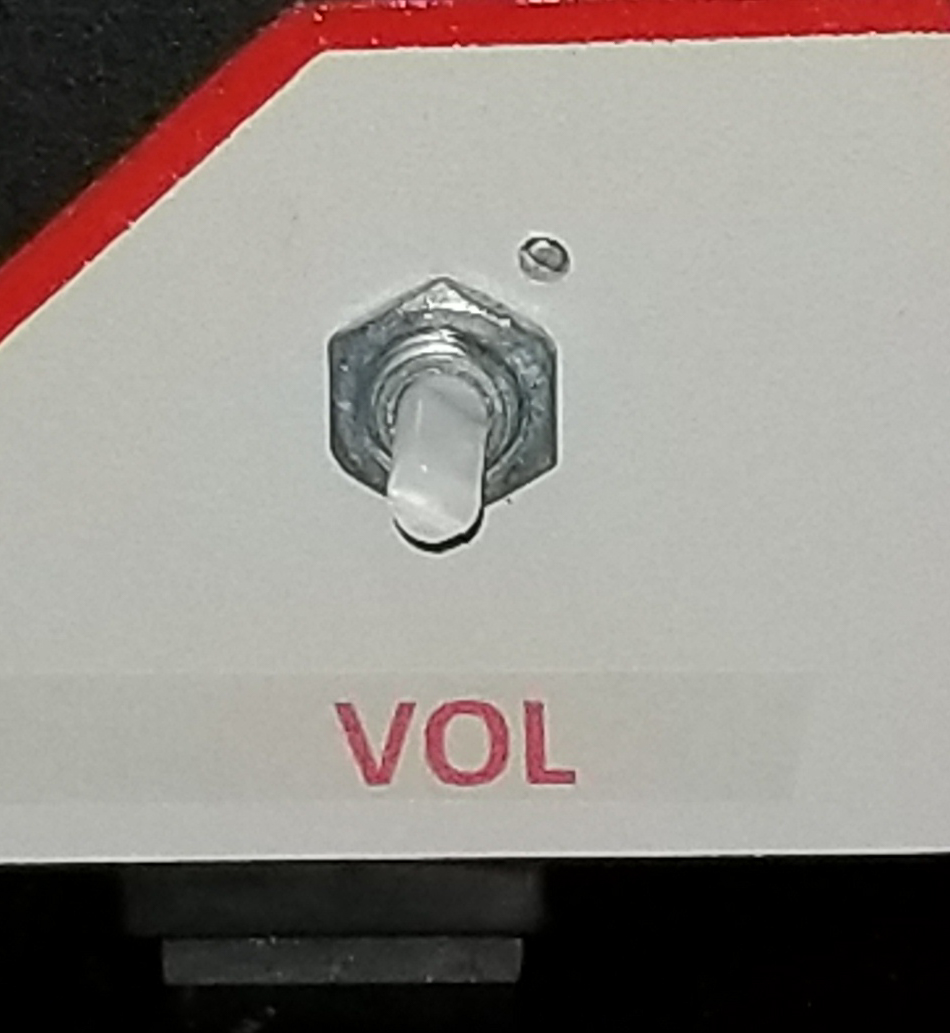

Power/Volume Knob Adapter

This project was mostly taking dimensions of a shaft and a knob's shaft

well with a micrometer and then designing and printing an adapter to

allow a knob to be installed on an undersized potentiometer shaft and

stay centered when it was rotated. It took several tries to get

the dimensions just right.

The design model, the shaft needing an adapter, and the knob with the

adapter inserted into it are shown above.

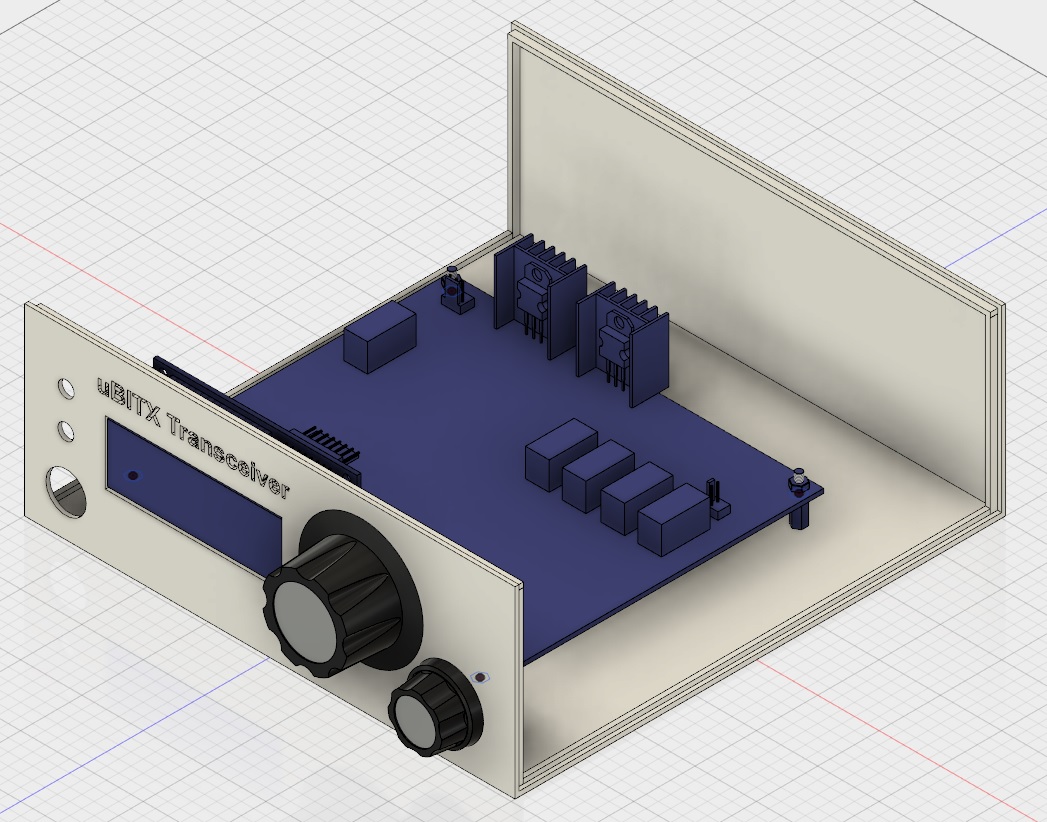

uBITX Enclosure - Work In Progress

This project is an unprinted work in progress and is currently still in

the design phase. Ultimately It is envisioned to be printed for a

friend who is getting a uBITX radio for his future birthday. This

project is attempting to solve some issues I've had with putting radios

into enclosures - specifically

- eliminating the need to cut, drill, or knibble holes into the

enclosure in order for parts, air, or sound to pass through the

enclosure walls

- having precise measurements of each needed penetration and modeling

them so that they can be placed properly to simply assemble the radio

parts

- being able to visualize 'what-if' design options easily, and make

design adjustments with minimum fuss and bother

After modeling component parts of the uBITX radio circuit boards, LCDs,

and stand-offs, the 'radio' model has been dropped into the model of the

enclosure to optimize fitment and try various designs for placement of

other parts (tuning control, power/volume control, microphone socket,

speaker/headphone socket, key socket, SO-239, power plug) while ensuring

no fouls with the radio or critical accesses to part of the radio.

The following is a model picture for one of the 'what-if' placements of

front panel parts.

Adding remaining front panel model parts, locating and adding rear panel

parts, creating a 'top' to the enclosure and 'attaching' a model of the

internal speaker remain.

Then it will be time to print. The bottom and the top are each

expected to take more than a day to print.

.